ServoBelt™ Rotary Stage

High-precision rotary motion control in an easy-to-integrate package.

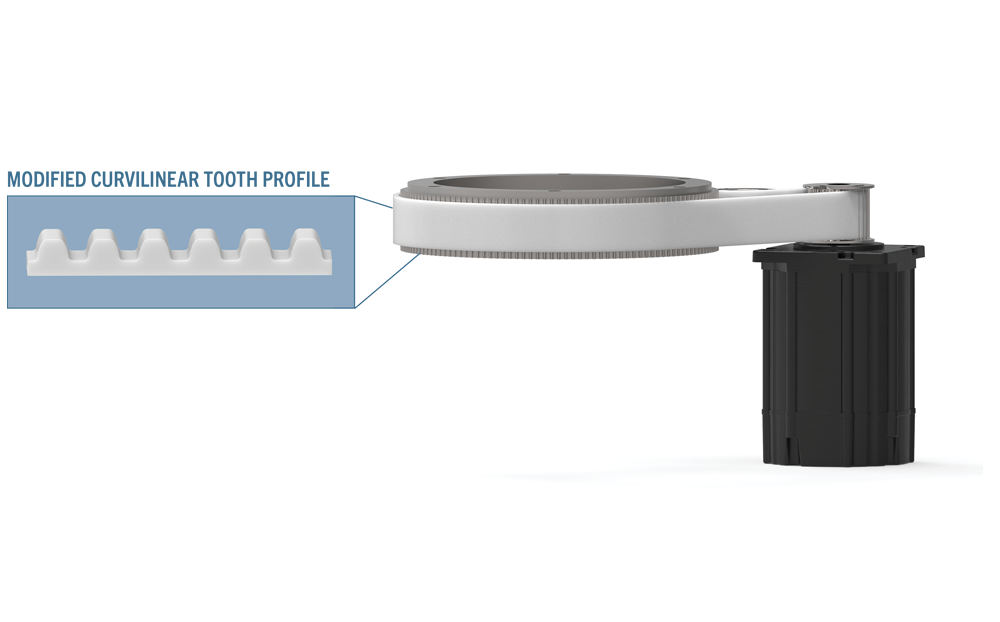

ServoBelt™ Rotary is a series of compact, high-torque motorized rotary stages that offer through hole size and speed comparable to direct-drive rotary tables costing thousands more.

- Room in the Middle. ServoBelt Rotary stages offer two different through hole configurations. Available with 50-, 100- or 200-mm center openings, our large through hole stages accommodate large bundles of power, signal and pneumatic conductors. They also make it easy to integrate laser and optical systems. Standard-sized models with 16- or 25-mm through holes offer a more economical choice when fewer utilities need to pass through the center of the stage.

- Direct Drive Performance. Designed for NEMA 23 and 34 motors, the ServoBelt rotary stages offer speeds up to 1,000 rpm, continuous torque to 6.6 N-m and resolution down to 0.16 arc-sec with Renishaw ring encoders or tape scales for partial rotation.

- Application Flexibility. ServoBelt Rotary stages support both continuous rotation and variable indexing applications.

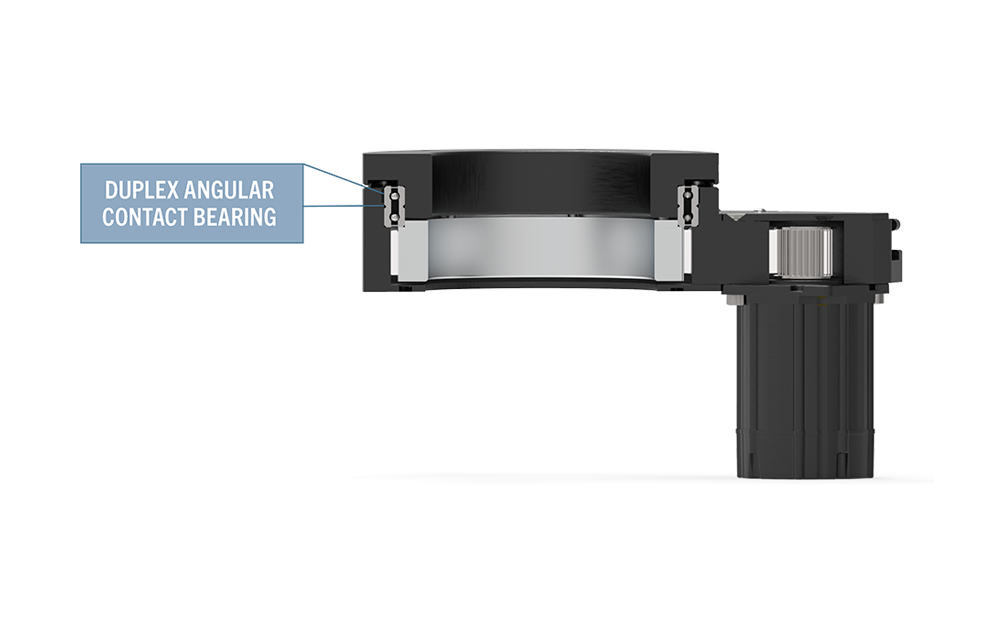

- Robust, Lubed-for-Life Bearings. ServoBelt Rotary stages incorporate large full duplex, angular contact bearings, imparting moment and load capacities far in excess of its usual application requirements. This excess load capacity translates into virtually limitless bearing life.

- Cost Effective. ServoBelt Rotary stages offer an economical solution for a variety of medium-duty rotary motion jobs such as driving carousel tables on packaging and assembly machines and providing fourth-axis rotary motion for laser cutting and mini CNC machines.

From gantry-mounted electromechanical assemblies, to cartesian robots with extended travel lengths, our engineered solutions are tailored to your needs. While our standalone stages must fit within a predefined physical space and tie into your machine’s motion control system, these larger turnkey systems free us up to optimize all aspects of assembly and controls integration.