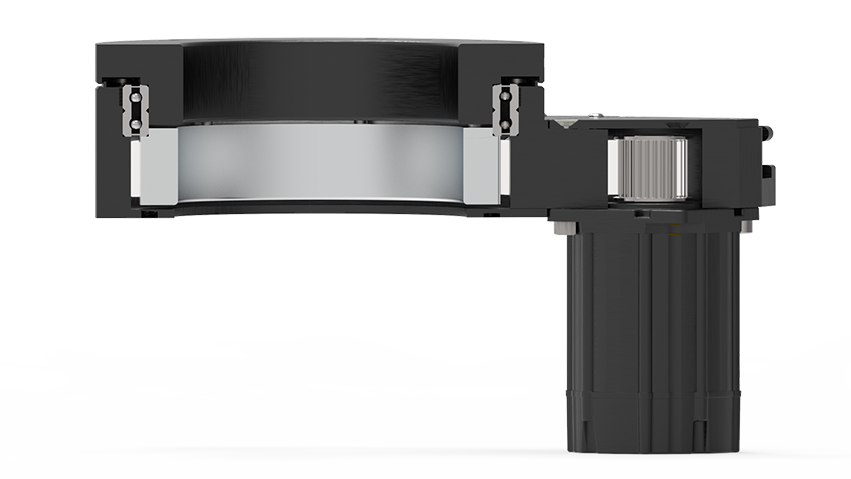

Bell-Everman ServoBelt™ RA Actuator

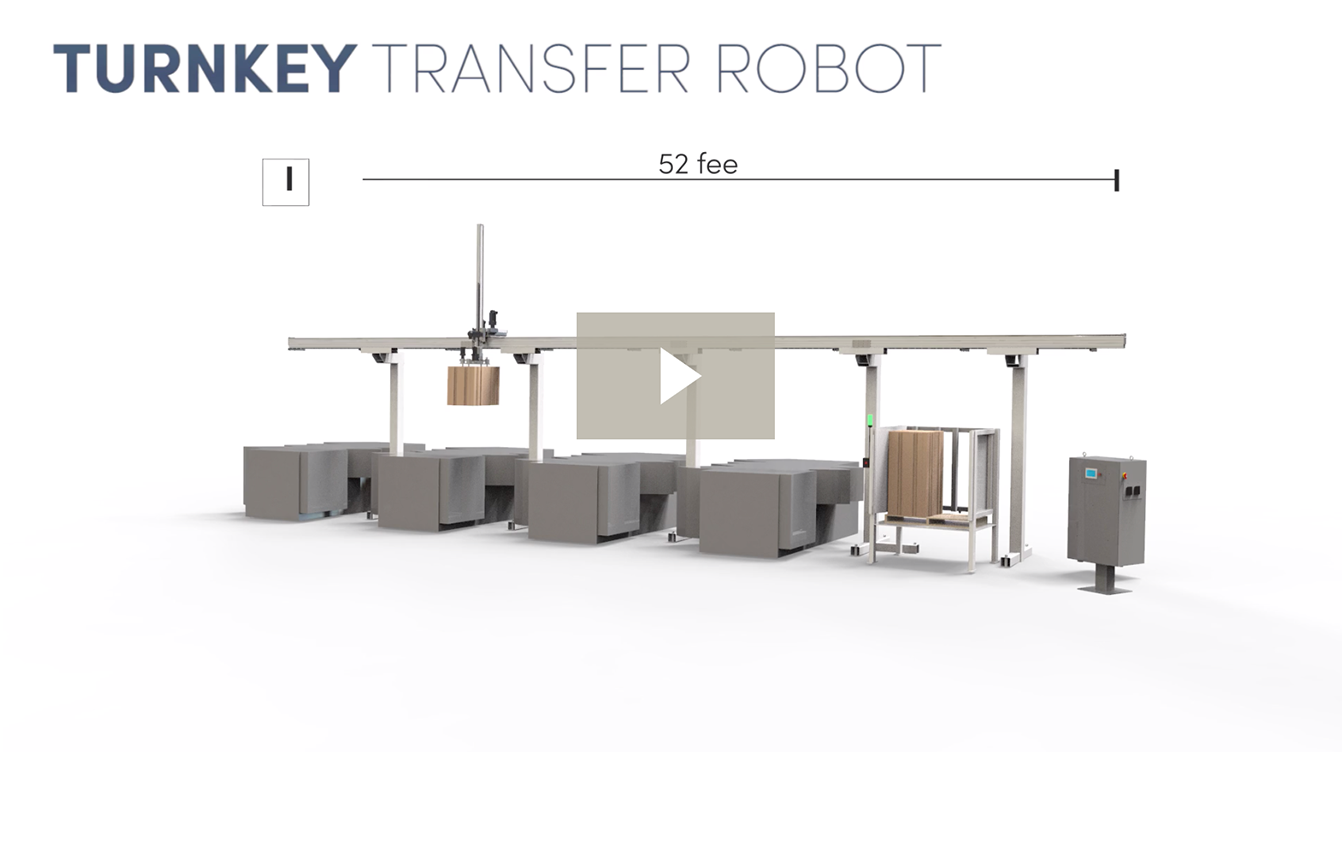

Based on our proven ServoBelt™ Linear technology, the new ServoBelt™ RA actuator serves as a high-performance, drop-in replacement for applications that have traditionally used rod actuators, pneumatic cylinders or even linear motors. Watch our latest video to learn more.