The Sky’s the Limit for ServoBelt™ Linear

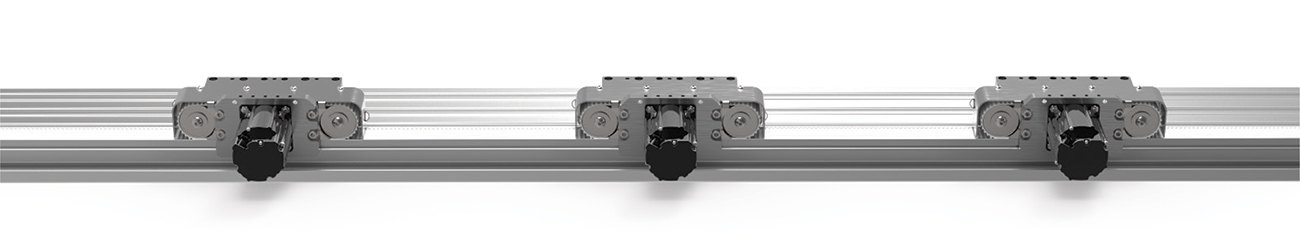

You might think everything has a limit. But when it comes to ServoBelt™ Linear actuators, our only limit is the physical space we work in. Unlike traditional single-belt drives, ServoBelt can support systems with unlimited travel lengths and multiple, independently controlled carriages on the same motion axis. Together, these qualities offer high performance and limitless scalability — all at a lower price point compared to high-end linear motor drives.

Unlimited Travel Lengths—Without the Drawbacks

At Bell-Everman, we achieve unlimited travel lengths thanks to a unique splicing method and build process that lets us join multiple sections of the chassis. In addition to overcoming travel length limitations, this splicing ability avoids the performance and commissioning difficulties that often arise in long-travel applications using other motion technologies. Effective long travel is expensive to do with linear motors, difficult to do precisely with rack and pinion and nearly impossible to do well with screws or conventional belts.

Multi-Axis Configurations Are Easy

We can easily create Cartesian motion systems, gantry robots and other multi-axis configurations. With multiple carriages traveling along the main axis and performing tasks independently of each other, these long-travel systems are gaining ground in applications like material handling and packaging. This ability is also a game-changer for Cartesian robots, as one chassis can support multiple processes.

Other benefits include:

Constant driveline stiffness. Unlike conventional belt drives, ServoBelt Linear’s active belt length is extremely short. This design minimizes belt stretch and creates constant driveline stiffness along the entire axis. Traditional recirculating belt drives or omega drives, on the other hand, experience inconsistent driveline stiffness depending on where the carriage is located on the axis. ServoBelt is, in fact, 34 times stiffer than a recirculating system of 1-meter travel!

No more belt sag. The belt tension in omega drives and recirculating belt drives needs to be high enough to avoid belt sag, which in turn can cause belt slap in the presence of loads. For this reason, many drive models incorporate a shelf that the belt runs near to avoid sagging, but these systems often have difficulties maintaining tension on large belts or long systems. These shelves can also create particulate debris. One result is that you need very specialized, costly hardware to properly tension the belt.

Backlash free. Tensioning of the belt preloads the belt mesh on either side of the pinion, resulting in backlash-free movement in either direction. This architecture never needs re-tensioning.

Configure Your Own System

To learn more about ServoBelt Linear—including how to use it for long-travel systems with multiple carriages—drop us a line. Or use our online quotation tool to configure your own system.